Ball Valves Guide: What Are They and How Do They Work?

What Is a Lined Ball Valve?

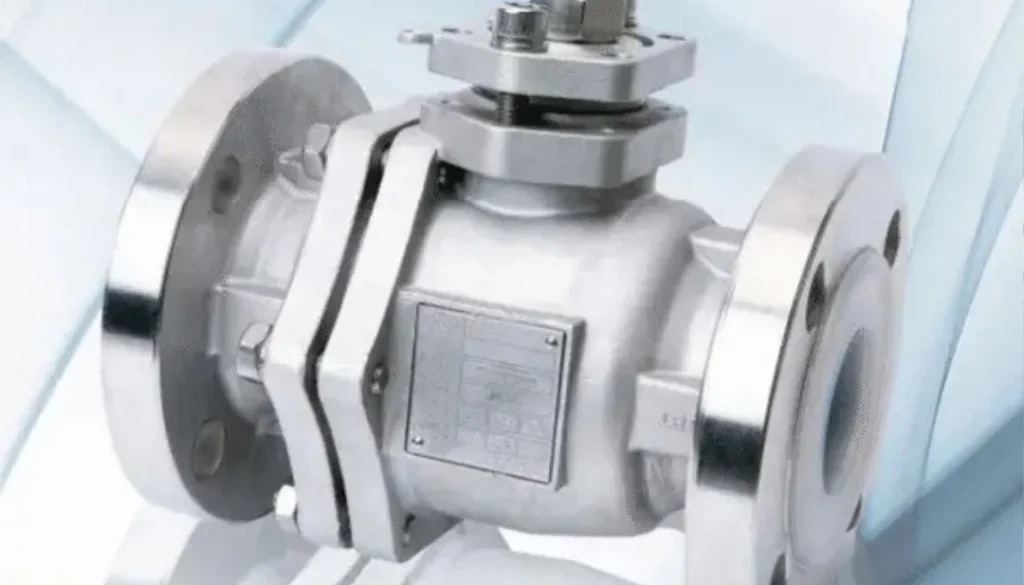

A ball valve is a flow control device used to turn liquids or gases on and off. It contains a small hollow ball with a hole; aligning the hole with the pipe allows flow, and rotating it 90° stops it. Ball valves are prized for their durability, tight sealing, and simple quarter-turn operation, making them ideal for shutoff functions across many industries.

A lined ball valve adds a protective lining, commonly PTFE (Teflon) or PFA to the valve body and ball. This lining shields the valve from corrosive or abrasive media, enhancing longevity and reliability.

Materials Used in Lined Ball Valves

- PTFE (Polytetrafluoroethylene): Known for outstanding chemical resistance and broad temperature range.

- PFA (Perfluoroalkoxy): Similar resistance, plus better mechanical strength under pressure.

- Carbon Steel/Stainless Steel: Typically used to make the ball and body, which is then coated with paint.

Advantages of Lined Ball Valves in Corrosive or Abrasive Systems

- Excellent resistance to acids, alkalis, solvents, and abrasive particles.

- Smooth internal surfaces, low friction and torque, plus easier flow with minimal pressure drop.

- Superior sealing and reliability, with longer lifespan and lower maintenance costs.

- Some versions offer self-lubrication, low flow resistance, anti-static properties, compact size and weight, ideal for high-pressure and high-temperature environments.

Common Industries Using Lined Ball Valves

- Chemical processing

- Pharmaceuticals

- Petroleum and petrochemical

- Pulp & paper

- Mining

- Power plants

- Water and wastewater treatment

Lined vs Unlined Ball Valves: Performance & Lifespan

Lined ball valves offer far greater corrosion resistance, durability, and less maintenance, ideal for aggressive media. They’re more expensive upfront but justify the cost through longer service life and reliability. Unlined valves are more affordable and suitable for non-corrosive fluids like water, oil, and gas.

Full-Port vs Reduced-Port

| Feature | Full-Port | Reduced-Port |

|---|---|---|

| Bore Size | Same as pipe diameter | Smaller than pipe |

| Flow Resistance | Minimal pressure drop | Increased pressure drop |

| Cost & Weight | Heavier and more expensive | Lighter and lower cost |

Maintenance for Lined Ball Valves

Key upkeep steps include:

- Inspect lining for damage or leaks.

- Lubricate the stem.

- Replace seals when worn.

- Clean to prevent debris-induced lining damage.

Limitations and Risks

- Temperature caps exist, e.g., PTFE/PFA around 260 °C, below all-metal valve limits.

- Pressure capacity is generally lower than all-metal counterparts.

- Lining may be compromised by particulate flow or debris.

- Larger sizes can be costly or more difficult to produce.

- Compatibility depends on the lining and fluid chemistry.

- On-site lining replacement is difficult.

Installation and Replacement Best Practices

- Shut down the system and relieve pressure.

- Drain the pipeline section.

- Remove the old valve carefully to protect flanges.

- Align the new valve to avoid stressing the lining.

- Use compatible gaskets; tighten bolts evenly.

- Test for leaks and proper operation.

- Gradually restore pressure and monitor performance.

Standards and Certifications: ASME B16.34

ASME B16.34 is the key standard for industrial ball valves with flanged, threaded, or welded ends. It sets requirements for pressure-temperature ratings, materials, dimensions, testing, and marking, ensuring safety and reliability in sectors like chemical processing, oil and gas, and power generation.

Other relevant ASME standards include B16.5 (flanges), B16.10 (dimensions), B16.11 (fittings), and B16.25 (buttweld ends).

Lined ball valves combine the simplicity and reliability of traditional ball valves with enhanced chemical resistance and durability, making them ideal for corrosive, high-wear environments. When choosing one, consider lining material, port configuration, maintenance needs, and whether it meets standards like ASME B16.34.