Check Valves: The Complete Guide

Check valves are an essential component in countless fluid handling systems. From water treatment plants to oil refineries, these valves quietly perform a critical role: ensuring that liquids and gases flow in only one direction. In this guide, we’ll explore what check valves are, how they work, the different types available, and why lined check valves are crucial for corrosive environments.

What Is a Check Valve and How Does It Work?

A check valve, also known as a non-return valve or one-way valve, is a mechanical device that allows fluid to flow in one direction while preventing reverse flow. Unlike other valves, they operate automatically without manual or electric control.

The basic mechanism relies on internal components such as a disc, ball, or diaphragm that move freely with forward flow and close tightly when the flow reverses. This prevents contamination, equipment damage, and inefficiencies caused by backflow.

Types of Check Valves

There are several types of check valves, each suited for different system designs and fluid characteristics:

- Swing Check Valve – Uses a hinged disc that swings open with forward flow and closes when flow stops or reverses. Best suited for low-velocity flows.

- Lift Check Valve – Functions with a disc or ball that lifts off the seat under pressure and drops back when flow stops. Ideal for high-pressure systems.

- Diaphragm Check Valve – Employs a flexible diaphragm that opens under pressure and seals tightly when flow reverses. Common in sanitary or corrosive applications.

Choosing the right type depends on flow conditions, installation orientation, and media properties.

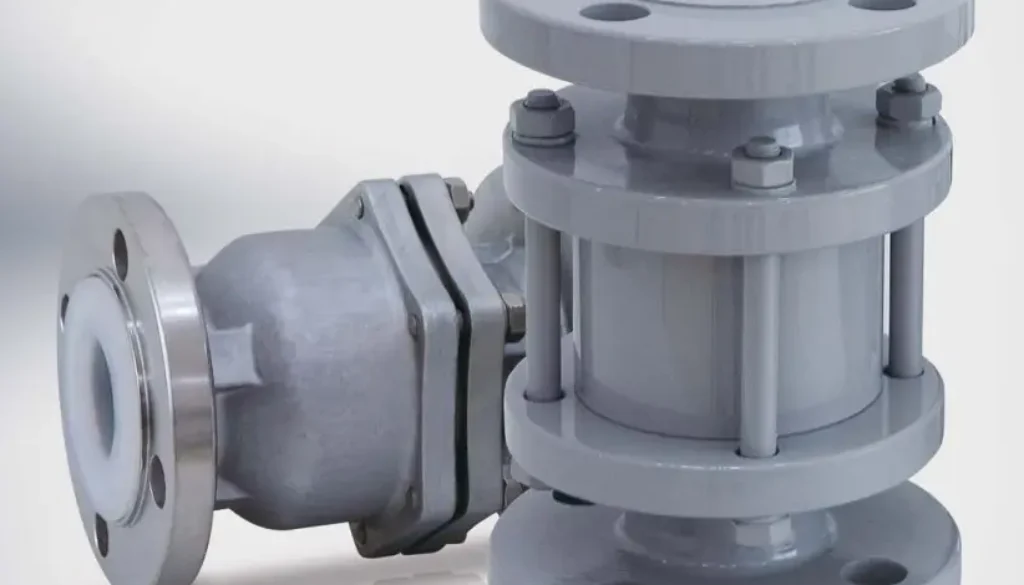

What Is a Lined Check Valve?

A lined check valve features an internal lining made from corrosion-resistant materials such as PTFE (Teflon) or PFA. This lining ensures that the process fluid never comes into direct contact with the valve’s metal body.

Common applications include:

- Chemical processing plants handling strong acids, alkalis, and aggressive solvents.

- Pharmaceutical manufacturing where product purity is critical.

- Water treatment facilities where abrasive or corrosive fluids are present.

By isolating the metal body, lined check valves extend service life, maintain fluid purity, and reduce overall maintenance costs.

Industries and Applications

Check valves are indispensable across a wide range of industries:

- Water and Wastewater Treatment – Preventing contamination of clean water by stopping backflow.

- Oil and Gas – Used in pipelines, refineries, and drilling operations to control hazardous and flammable fluids.

- HVAC Systems – Maintaining correct flow of refrigerants, coolants, and water.

- Pharmaceutical and Food & Beverage – Preventing cross-contamination in sanitary systems.

- Power Generation – Controlling steam, water, and cooling systems in turbines and boilers.

- Plumbing – Protecting households and commercial buildings from backflow contamination.

Benefits of Lined Check Valves in Corrosive Environments

The main advantage of lined check valves is their superior resistance to corrosion. The non-reactive lining prevents metal contamination, maintains product purity, and enhances overall system safety.

Other benefits include:

- Extended lifespan by protecting key components from wear.

- Lower maintenance costs due to reduced corrosion-related failures.

- Improved reliability in harsh chemical environments.

How to Select the Right Check Valve

Selecting the correct check valve is critical for efficiency, safety, and longevity. Key considerations include:

- Product characteristics: viscosity, temperature, and corrosiveness of the fluid.

- System conditions: flow rate, cracking pressure, and backflow prevention needs.

- Installation factors: orientation, available space, ease of maintenance, and cost versus durability.

An incorrect selection can lead to inefficiencies, costly downtime, or premature valve failure.

Common Issues and Failure Modes

Like all mechanical components, check valves are subject to wear and failure. Typical problems include:

- Blockage – Debris or a stuck disc can prevent normal flow.

- Leakage – Worn sealing surfaces or trapped debris can allow reverse flow.

- Chatter or vibration – Caused when flow is too low to fully open the valve, resulting in noisy oscillation.

Preventive maintenance and correct sizing are essential to minimise these issues.

Maintenance and Inspection of Check Valves

Routine maintenance helps keep check valves functioning reliably. Inspections may include:

- Monitoring system pressure and flow for irregularities.

- Listening for unusual sounds such as whistling or hammering.

- Inspecting internal components during shutdowns for wear, pitting, or debris.

Regular cleaning and flushing of the system reduces the risk of blockages and prolongs valve life.

Can Check Valves Be Repaired or Refurbished?

Yes, check valves can often be repaired. The process involves disassembly, cleaning, inspection, and replacement of worn components such as discs, springs, or seats. Once reassembled, the valve is tested before being reinstalled.

Refurbishment can extend the life of a valve and reduce replacement costs, particularly for large or specialised valves.

How Do Check Valves Affect System Efficiency?

Check valves influence system performance primarily through the pressure drop they create. While they introduce some resistance to flow, their role in preventing backflow far outweighs this drawback. By safeguarding pumps, compressors, and pipelines, they help maintain overall system efficiency and reliability.

Final Thoughts

Check valves may be simple devices, but their role in protecting fluid systems is vital. From preventing contamination in water supplies to managing corrosive chemicals in industrial plants, they ensure safe and efficient operation.

When selecting a valve, consider your system’s fluid characteristics, operating conditions, and the need for corrosion resistance. In harsh environments, lined check valves provide added durability.