Lined Pumps: What They Are, Why They Matter, and How to Choose

Lined Pumps: What They Are, Why They Matter, and How to Choose Wisely

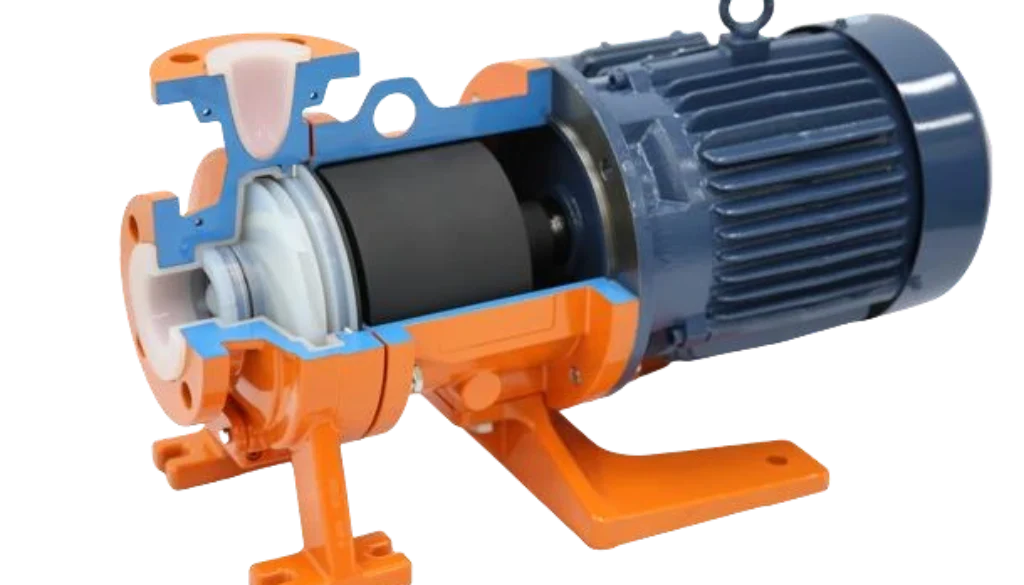

In industries where fluids are corrosive, abrasive, or otherwise aggressive, standard pumps often wear out quickly. Lined pumps are specialised units where the internal surfaces exposed to fluid are lined with a resistant material. The lining protects the structural metal, often steel, from corrosion, chemicals, and abrasion, while the outside shell provides the necessary strength and rigidity.

Materials Used for Pump Lining

The materials used in pump linings are central to their effectiveness. PFA, or perfluoroalkoxy alkane, is widely chosen because of its exceptional chemical resistance and its ability to handle high operating temperatures. This makes it well suited to applications involving acids, bases, and solvents. PTFE, or polytetrafluoroethylene, is another common choice because of its inertness and wide compatibility with aggressive chemicals. Rubber linings are frequently applied in slurry environments, as rubber can absorb impact and resist abrasive wear in a way that rigid plastics cannot. In addition, materials such as polypropylene (PP) and ethylene tetrafluoroethylene (ETFE) are sometimes employed for lighter duty processes, offering a balance of corrosion resistance and mechanical strength. Each lining material presents trade-offs in terms of chemical compatibility, temperature limits, and durability under mechanical stress, which is why careful selection is so important.

Why Use Lined Pumps in Corrosive or Chemical Environments?

The main reason industries use lined pumps is their ability to resist corrosion in highly aggressive environments. Corrosion of pump components not only shortens service life but also poses risks of leaks, structural failure, and costly downtime. By providing a protective barrier, the lining ensures safer operation, especially when dealing with hazardous or toxic fluids. This improves workplace safety and reduces environmental risk. Another significant benefit is longer service life, as lined pumps can operate for years without the rapid deterioration often seen in unlined units. Although their upfront cost is higher, the lower frequency of replacements and repairs means they deliver better long-term value. The ability of lined pumps to combine safety, durability, and cost-effectiveness makes them an indispensable choice for handling corrosive media.

Main Types of Lined Pumps

Here are common types or designs of lined pumps used across industry:

| Type | How Lining is Used | Typical Applications |

|---|---|---|

| Centrifugal lined pumps | Impeller, casing or other wetted parts lined with chemical-resistant polymer or fluoroplastic | Transfer of aggressive chemicals, large volumes, moderate viscosity fluids. |

| Magnetic drive lined pumps | Casing and internal surfaces lined; pumps designed without mechanical shaft seals to avoid leaks | For hazardous or toxic chemicals, when leakage must be avoided. |

| Rubber lined slurry pumps | Rubber lining to resist abrasion from solids in slurry, often in mining or aggregate/ sand applications | Handling slurry, wet sand, solids-laden fluids. |

| Plastic or fluoroplastic lined process pumps | Using PP, ETFE, etc., as the liner for corrosion resistance in light to moderate duty chemical processes | Light acids, bases, less abrasive or particulate fluids. |

Choosing the Right Lined Pump for Your Application

Selecting the right lined pump requires a detailed understanding of the process fluid and operating environment. The first consideration is chemical compatibility, since some lining materials degrade when exposed to certain chemicals or oxidisers. If compatibility is overlooked, even the strongest lining may fail prematurely. Temperature and pressure limits are also critical, as fluoropolymers and rubber linings vary in their ability to withstand extremes. The nature of the fluid must be considered too, particularly when it contains solids or abrasive materials. In such cases, rubber linings may provide better wear resistance than plastics.

Flow rate and viscosity influence the pump’s internal geometry and the effectiveness of the lining. If a pump is chosen without regard to these properties, efficiency and durability may suffer. Leak prevention is another important factor, especially in hazardous chemical handling, where magnetic drive or sealless designs provide greater safety. Finally, practical factors such as regulatory compliance and spare parts availability influence the overall decision. Each of these considerations shows that pump selection is not simply about cost but about balancing operational needs with reliability and safety.

Performance Benefits and Trade-offs of Lined Pumps

The performance advantages of lined pumps are clear. They provide far greater resistance to corrosion and chemical attack than unlined pumps, ensuring a longer lifespan in demanding environments. This reduces downtime, minimises replacements, and enhances overall workplace safety. Because they resist wear, lined pumps are often more reliable, and their smooth internal surfaces can reduce fouling or scaling. These benefits explain why industries continue to adopt lined pumps despite their higher initial investment.

There are trade-offs however. Lined pumps are more expensive upfront and their linings can impose limitations on temperature, pressure, and mechanical loads. Some linings do not handle mechanical stress or impact well, particularly when sharp or large solids are present. Repairing or relining is also more challenging than servicing a standard pump, often requiring full replacement of components once the lining is compromised.

Handling Abrasive or Particulate-Laden Fluids

When abrasive or particulate-laden fluids must be pumped, the lining material and pump design become even more critical. Rubber linings are often the preferred choice in slurry handling because they can absorb impact and resist wear more effectively than rigid fluoroplastics. Pump designs with larger clearances and robust impellers are necessary to manage solids without damaging the lining. Upstream filtration or screens can further protect the pump by removing oversized particles before they cause harm.

The operating conditions must also be carefully controlled. If turbulence within the pump is too high, abrasive wear on the lining can accelerate. Maintaining steady flow and avoiding dry running are important strategies to prolong pump life. The ability of rubber-lined pumps to withstand these conditions makes them particularly valuable in industries like mining and sand processing, where abrasive slurries are common.

Maintenance Requirements and Challenges

Maintaining lined pumps involves more than routine servicing. Regular inspections are essential to identify cracks, blistering, or delamination in the lining before they compromise safety. Seals and joints, especially at flanges where lining meets metal, must be closely monitored for early signs of leakage or wear. Keeping pumps within their rated operating limits for flow, temperature, and pressure is vital to prevent overstressing the lining. Cleaning schedules should be maintained to avoid chemical or particulate build-up, which can shorten lining life.

The challenges often lie in reparability. Once a lining is significantly damaged, relining may not always be feasible, and complete component replacement is often necessary. Ensuring that the pump is manufactured with high-quality bonding or moulding processes helps reduce the risk of premature liner failure. While these maintenance demands can be intensive, they are a small trade-off compared to the risks of pump failure in critical operations.

Lifespan of Lined Pumps and Factors That Affect It

The service life of a lined pump depends heavily on its operating conditions and maintenance. Pumps with well-chosen lining materials and strong manufacturing quality can last for many years, even in corrosive or abrasive service. Duty cycle plays a large role, as pumps that run continuously may wear faster than those used intermittently. Maintenance discipline also determines lifespan, since early detection of liner wear prevents catastrophic failure.

Other factors such as filtration, process control, and avoiding sudden pressure or temperature spikes extend pump life. While no pump lasts indefinitely, careful specification and upkeep can significantly improve lifespan.

Cost Versus Investment: Is It Worth It?

The question of whether lined pumps are worth the extra cost can be answered by looking at the total cost of ownership. While they are expensive to purchase, the reduced need for repairs and replacements can offset the initial investment. Downtime is minimised, which is particularly valuable in industries where interruptions are costly. Safety improvements and environmental protection also add value by reducing the risk of chemical spills or leaks.

There are cases where unlined pumps may suffice, particularly when fluids are mild and non-corrosive. In such situations, the additional expense of a lined pump may not provide a strong return. However, in most applications involving aggressive fluids, lined pumps prove to be the more cost-effective and reliable option in the long run. They combine durability, safety, and efficiency, making them a worthwhile investment for demanding industries.

Lined pumps are an essential solution for managing aggressive fluids safely and efficiently. By selecting the right lining material and pump design, industries can achieve longer service life, greater safety, and improved cost-effectiveness. Although they require careful maintenance and involve higher upfront costs, their benefits far outweigh the drawbacks. For corrosive, abrasive, or hazardous applications, lined pumps remain a cornerstone of reliable fluid handling.